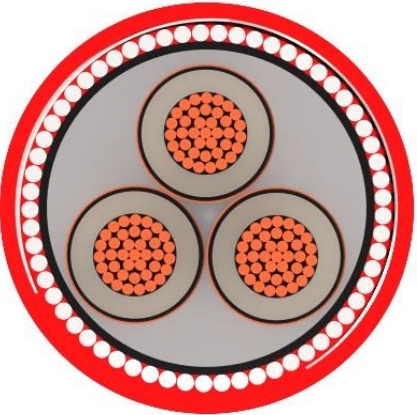

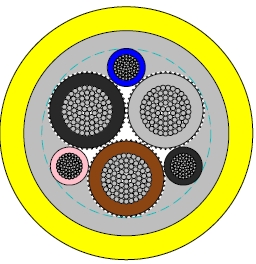

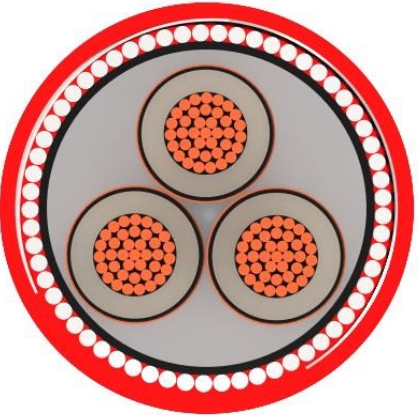

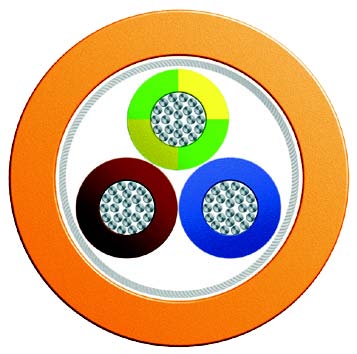

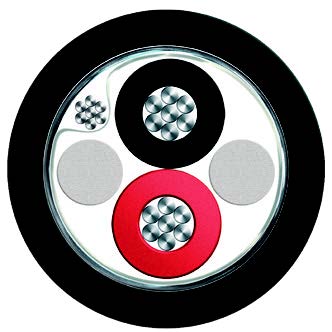

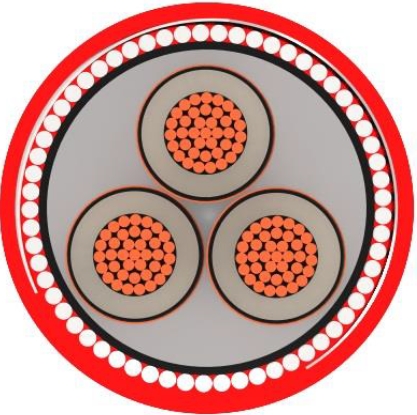

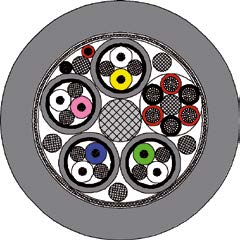

The SHD-GC type three-core circular power cable is specifically designed for heavy-duty scenarios such as mining, tunneling, and construction projects. It is ideal for use with heavy equipment such as longwall coal cutters, continuous mining machines, excavators, and drills. The cable features a CPE jacket, providing exceptional durability, oil resistance, and weatherability, ensuring stable power transmission and safe operation of equipment. It serves as an excellent power solution for machinery in the mining, construction, and related industries.

STANDARDS

ICEA S-75-381/NEMA WC 58

ASTM B 172

ASTM B 33

CAN/CSA C22.2 No. 96

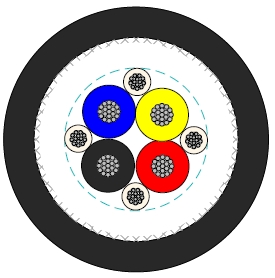

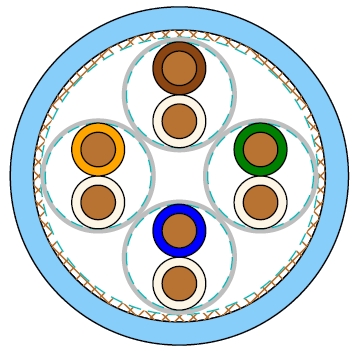

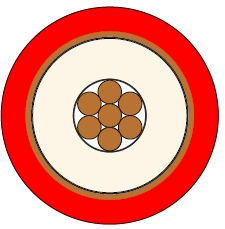

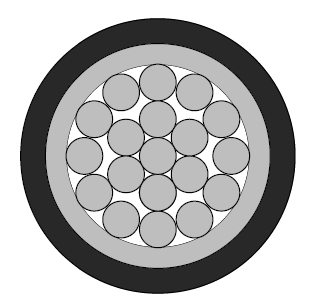

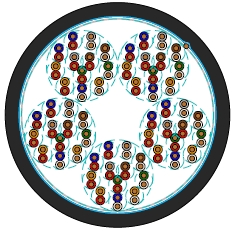

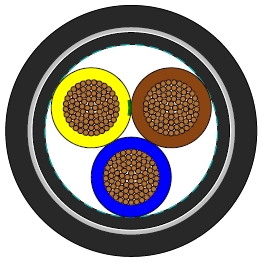

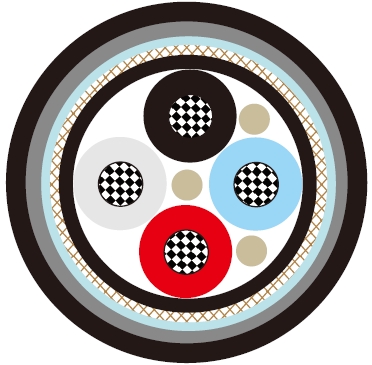

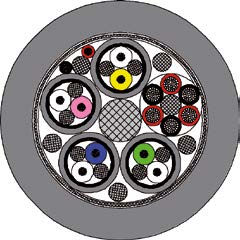

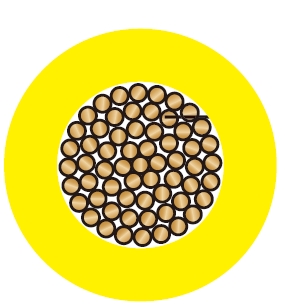

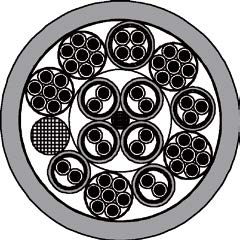

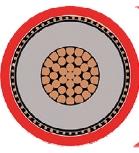

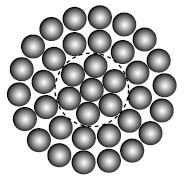

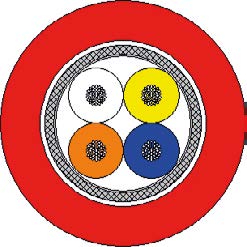

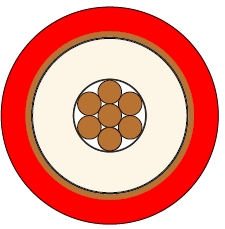

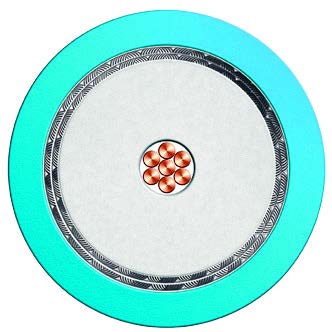

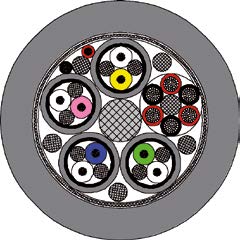

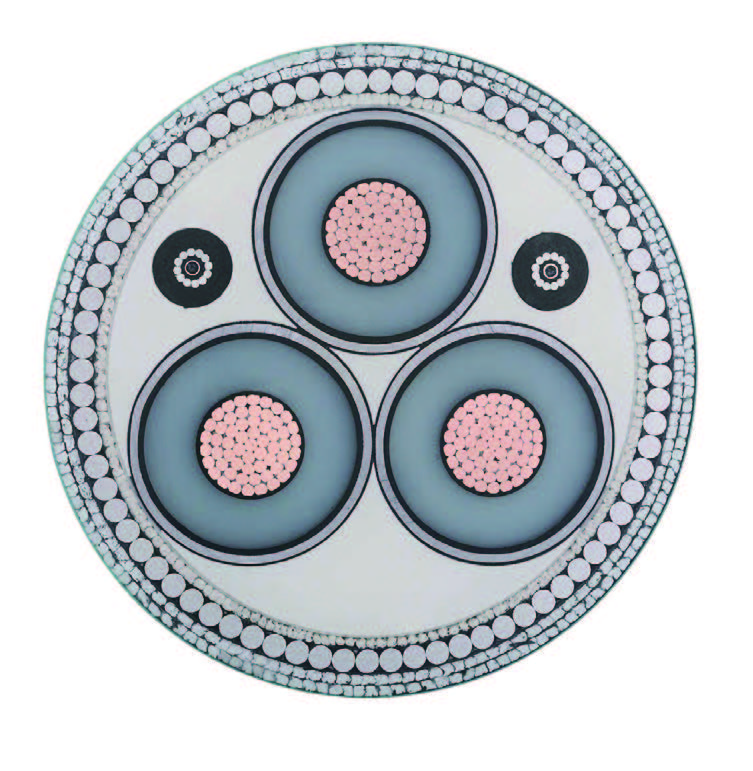

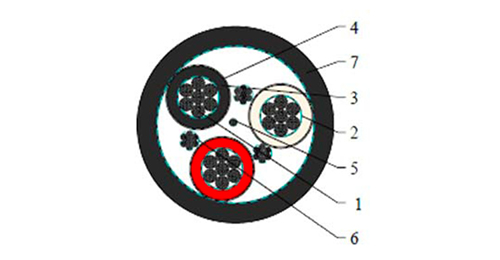

| Conductors | Stranded annealed tinned copper conductor. |

|---|---|

| Conductor Shield | Conducting layer. |

| Insulation | Ethylene Propylene Rubber (EPR). |

| Insulation Shield | Conducting tape + Tinned copper/textile braid. |

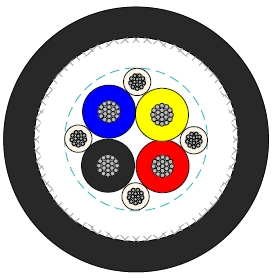

| Ground Check Conductor | Tinned copper with a yellow polypropylene insulation. |

| Grounding Conductor | Tinned copper conductor. |

| Jacket | Reinforced extra-heavy-duty Chlorinated Polyethylene (CPE), black. |

Other jacket materials such as CSP/PCP/NBR/PVC are available upon request.

Two-layer jacket with reinforcing fibre between the two layers can be offered as an option.

| Minimum Bending Radius | 8×OD |

|---|---|

| Maximum Conductor Operating Temperature | +90℃ |

| Construction | No. of Strands | Grounding Conductor Size | Ground Check Conductor Size | Nominal Insulation Thickness | Nominal Jacket Thickness | Nominal Overall Diameter Height×Width | Nominal Weight | Ampacity | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of cores × AWG/kcmil | - | AWG/kcmil | AWG/kcmil | inch | mm | inch | mm | inch | mm | lbs/kft | kg/km | A |

| 3×4 | 259 | 8 | 8 | 0.150 | 3.8 | 0.205 | 5.2 | 1.94 | 49.3 | 2308 | 3594 | 122 |

| 3×2 | 259 | 6 | 8 | 0.150 | 3.8 | 0.220 | 5.6 | 2.12 | 53.8 | 2920 | 4554 | 159 |

| 3×1 | 329 | 5 | 8 | 0.150 | 3.8 | 0.220 | 5.6 | 2.21 | 56.1 | 3292 | 5104 | 184 |

| 3×1/0 | 259 | 4 | 8 | 0.150 | 3.8 | 0.220 | 5.6 | 2.32 | 58.9 | 3675 | 5700 | 211 |

| 3×2/0 | 329 | 3 | 8 | 0.150 | 3.8 | 0.235 | 6.0 | 2.46 | 62.5 | 4304 | 6593 | 243 |

| 3×3/0 | 413 | 2 | 8 | 0.150 | 3.8 | 0.250 | 6.4 | 2.62 | 66.5 | 5200 | 7738 | 279 |

| 3×4/0 | 532 | 1 | 8 | 0.150 | 3.8 | 0.250 | 6.4 | 2.75 | 69.8 | 5840 | 8713 | 321 |

| 3×250 | 608 | 1/0 | 6 | 0.150 | 3.8 | 0.250 | 6.4 | 2.89 | 73.4 | 6774 | 9948 | 355 |

| 3×300 | 741 | 1/0 | 6 | 0.150 | 3.8 | 0.265 | 6.7 | 3.04 | 77.2 | 7423 | 11384 | 398 |

| 3×350 | 888 | 2/0 | 6 | 0.150 | 3.8 | 0.280 | 7.1 | 3.21 | 81.3 | 8543 | 12739 | 435 |

| 3×500 | 1221 | 4/0 | 6 | 0.150 | 3.8 | 0.295 | 7.5 | 3.56 | 90.4 | 11260 | 16757 | 536 |

Ampacity-Based on a conductor temperature of 90℃ and an ambient air temperature of 40℃, per ICEA S-75-381.